Are Garage Ceiling Storage Racks Safe?

You know the ones - The suspended-load, hanging metal racks. You’ve seen them in advertisements, packed full and suspended above a car or doorway. Generally speaking, they are made in Asia, from steel, and they go by several different names and sold by many different companies. They seem like a great garage storage solution for people looking to get things off the floor.

Danger! Alert! Warning!

Unfortunately, there are HUGE problems with them.

Not just the numerous recalls; the latest of which can be seen here:

(That particular recall was the result of at least one person being injured on the neck and face.) The recall affected the bolts used to attach the system to the ceiling, but the problem is MUCH DEAPER than that.

Generally speaking, no. Ceiling-hung garage storage racks are not safe. The issue is multifaceted.

Firstly, let’s talk about the way homes are built.

Think about a home that is built out of solid lumber: We call those “stick built” homes. You’ll still see pine and fir studs in the walls, of course, and ceilings were once made out of solid wood as well.

These days, roofs and ceilings are another story.

Rarely are homes built with solid lumber ceiling joists anymore, especially when it comes to the joists that form your garage ceiling. As the old saying goes, “They don’t make ‘em like they used to.”

Engineered I-Beam Joists

In most homes built since 2000, builders have used engineered I-Joists for long spans, like garage ceilings.

Engineered I-joists are made of OSB (Oriented Strand Board) that is similar to particleboard. Wood flakes (called “strands”) are glued together and compressed to make a thin sheet. This sheet forms the vertical portion of the beam.

The horizontal parts (called “flanges”) were, at one time, made from 2x4 lumber. For several years now, however, flanges are made of OSB too. There is ABSOLUTELY NO SOLID WOOD in the I-joist and it is bonded together with glue.

The picture above is the best case scenario for engineered I-joists. Most I-joists that we see daily have only 7/16”-thick vertical structure or less.

Builders use engineered I-joists because they do what they are designed to do; span long distances and support the roof structure with enough strength left over for variables like snow and roof workers to do short-term repairs. They also provide a way to network cables and pipes throughout a structure in a way that neatly hides them in the space between the ceiling of the garage and the floor of the room above the garage.

So, how does all this relate to ceiling-hung garage storage?

Engineered I-Joists ARE NOT DESIGNED TO SUPPORT A LOAD HANGING BELOW. Except for light things like sprinkler heads, electrical outlets, or light ceiling fans, the manufacturers of these I-joists do not design them to support these suspended-load systems.

We’re not kidding. We called every major manufacturer of engineered I-joists and they all said the same thing:

“If you attach a suspended load to our joists, you void the manufacturer’s warranty.”

However, we wanted to do better. We wanted this in writing from a credible, authoritative source. All of these manufacturers are part of a trade group called the Engineered Wood Association. (This is a part of APA - the American Plywood Association.)

In the APA Design and Construction Guide for I-Joists, it says on Page 8:

You may be asking right now, “How would I know if I have engineered I-joists in my home?”

You wouldn’t, at a glance. Unless you saw your house being constructed and knew to watch for them. For some homeowners, calling the builder is an option. Otherwise, you’ll need to use a snake camera and cut a hole through the ceiling covering to see. (In most cases, this is sheetrock.)

In short, it’s not easy to know if I-beams were used to construct your home.

This is where things get dicey.

Do the makers of these ceiling-hung garage storage systems know that this is an issue?

Yes, they do. Unfortunately, these companies are not being completely upfront about the dangers that these systems present.

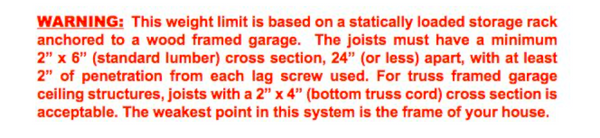

Here is one “warning” that we found in a suspended-load system’s installation instructions:

While no clear language about engineered i-beam joists appears here, the wording is clever.

“Standard Lumber” is a dead giveaway. They mean to say “solid lumber”, meaning, a board cut from a tree. As stated earlier, very few homes are built in this manner today and for many years in the past.

“...at least 2 inches of penetration from each lag screw used.” This is impossible with even the best engineered I-beams.

Once the lag penetrates the I-beam at all, it weakens the I-beam permanently. If you were to continue going, and you were aligned with the vertical OSB portion of the I-beam, their included lag screws are likely to be thicker than the vertical beam itself. This would further weaken the beam and, once weight is applied, is very likely to result in structural failure.

This could occur quickly or over a period of a few years. The failure of these systems, putting people at risk, is the core of the problem.

Most homeowners would never know to even consider these issues. I personally, didn’t know about the existence of engineered I-beams until a contractor brought them to my attention.

If a homeowner buys one of these systems and follows the instructions, the stud finder would indicate that there is something “solid” behind their ceiling’s sheetrock.

Without another thought, the homeowner may drive the lag bolt into what they think is wood, voiding the warranty and doing serious structural damage to their ceiling and home.

Suspended-Load Racks are Difficult to Install

Yes, we’ve seen the elaborate mechanisms that some YouTube DIYers have used to make it a little easier. The fact remains, however, that working above your head for a long period of time is tiring.

It’s not so much the physical discomfort that causes long-term problems. It’s the lack of accuracy that the fatigue causes.

We’ve seen it, many times. Here is a video that we shot during one of our factory installations. The homeowner asked us to remove their overhead rack because they felt "unsafe."

Most ceiling-hung systems are attached to the ceiling at four or six points. This is itself a problem since you are guaranteed to have two of these load-supporting points compromising a single joist.

Moreover, it’s common to find that only three of the four support points are correctly installed in the ceiling with the fourth attached only to sheetrock. While the manufacturer cannot be directly held responsible for faulty installation, it is the difficulty of the installation that causes the repeated problem.

That’s Why We Start with Quality Engineering

Every time you go to your car, you’re walking under your garage storage system. You rely on a durable, dependable shelving to safely hold your belongings UP and OUT OF THE WAY.

So, the choice is immediately clear: Do you want the weight of your stuff suspended over you and your family’s heads from an engineered I-beam? Do you want to rely on a particle board joist for which the warranty has already been violated?

The better way to handle that weight is to safely send that weight through a real wood stud safely to the footing of your home!

That’s why the Triangle Builders Guild commissioned Rhino Shelf. They knew the dangers of the ceiling systems - They build these homes every day. It’s a safety issue and not to be left up to an OSB joist system.

Rhino Shelf garage storage shelves started with engineering. If it is designed to be safe from the beginning, with all of the foresight, calculations, testing and quality materials that necessitates, then it will be a winner with homeowners across the nation. To keep quality high, we’ve also kept the design and manufacturing of our product in the USA. Maybe it costs us a little more, but our eyes are constantly on our work and focused on shipping a quality product.

We made it easy to install and it looks great too!